Hybrimet Applications

HybriMet Net Shape Nanocomposite cermets offers the following advantages for a variety of applications:

- Hardness of ceramics with toughness of steel

– Allows large parts to be fabricated – not flaw sensitive as monolithic ceramics

– No expensive or critical heat treatments required - Near-nano WC, hierarchically structured

– >1400VHN (2200-2400VHN)

– >20Mpa/m toughness (greater than tool steel) - No measurable wear, loads up to 480KSI

- Machinable

- Low friction in low viscosity lubricant

– e.g., Salt water, diesel fuel - Does not tear up mating surfaces – self lapping

– Targeted Use in highly loaded hybrid bearings - Fabricated using spark plasma sintering of n-WC and n-TiN cermet engineered starting powders

Wind Turbine Bearings |

Radial Bearings |

Balls for Roller Bearings |

Ball Valves |

Poppet Valves |

Seat Valves |

Relief Valves |

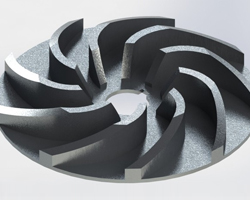

Centrifugal Pump Impellers |

Thrust Washers |

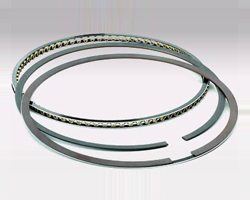

Ring Seals |

Stamping Tools |

Bushings |

Pistons |

Gears |

Cylinder Liners |