HybriMet™

Overview

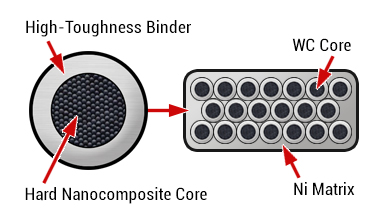

HybriMet™ is the first commercially available hierarchical nanocomposite cermet, which provide low friction in low/no viscosity lubrication system. HybriMet™ is fabricated using spark plasma sintering on nano tungsten-carbide and titanium-nitride cermets. HybriMet™ materials are consolidated using proprietary processes and are easily castable in a variety of shapes and can be machined to tight tolerances.

HybriMet™ is a family of hierarchically structured ceramic-metal (cermet) nanocomposites with superior wear resistance, lower friction, higher fracture toughness, and improved reliability and durability compared to conventional bearing materials including tool steels and ceramics. HybriMet™ offers the frictional and life benefits of ceramics such as Si3N4, but with the toughness and ease of manufacture and reliability of steel.

Our patented structure combines high hardness nanocomposite zones with tough ductile zones in an engineered manner. The hard ceramic core can be virtually any nitride or carbide (such as Titanium Nitride or Tungsten Carbide).

Value Proposition

- Hardness of ceramics with toughness of steel

– Allows large parts to be fabricated – not flaw sensitive as monolithic ceramics

– No expensive or critical heat treatments required - Near-nano WC, hierarchically structured

– >1400VHN (2200-2400VHN)

– >20Mpa/m toughness (greater than tool steel) - No measurable wear, loads up to 480KSI

- Machinable

- Low friction in low viscosity lubricant

– e.g., Salt water, diesel fuel - Does not tear up mating surfaces – self lapping

– Targeted Use in highly loaded hybrid bearings - Fabricated using spark plasma sintering of n-WC and n-TiN cermet engineered starting powders

HybriMet-W comparison with Steel and Silicon Nitride:

| Property | HybriMet W-Cermet | Bearing Steel (440C, 52100) | Silicon Nitride |

|---|---|---|---|

| Wear Resistance | Excellent | Fair | Very Good |

| Corrosion Resistance | Excellent | Poor, not compatible in sea water | Excellent |

| Fatigue Life | Very Good | Excellent | Good, but random failures in bearings |

| Fracture Resistance | Excellent | Excellent | Poor |

| Temperature Capabilities | Excellent | Fair | Excellent |

| Material Weight | Fair | Good | Excellent |

| Machinability / Processability | Good | Good | Poor |

HybriMet-W comparison with Steel and Silicon Nitride:

| Property | HybriMet CoWC | HybriMet NiWC | 440C Steel | 52100 Steel | Silicon Nitride (Ceradyne Ceralloy® 147) |

|---|---|---|---|---|---|

| Hardness (GPa) | 22.95 | 20.07 | 6.8 | 8.5 | 14.2 – 16.2 |

| Elastic Modulus (GPa) | 486.5 | 435.2 | 200 | 210 | 310 |

| Bulk Fracture Toughness (MPa/m2) | 20.4 | 20.2 | 23.1 | 16-19 | 4.5 – 6 |